Bricks

Insulating brick

- AL2O3

- Insulating brick

- Erosion resistance

- Low thermal conductivity

- Product description:

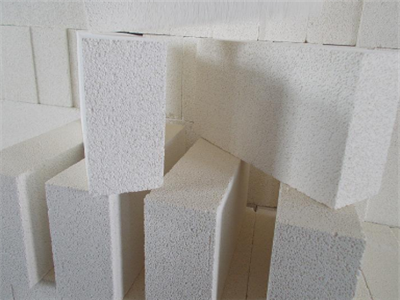

Insulating brick

Lightweight corundum brick is also called alumina insulation brick, foam corundum brick or foam alumina brick. Lightweight refractories containing more than 90% alumina and mainly composed of corundum. High refractoriness and small volume shrinkage of reburning. The compressive strength is 4 ~ 25MPa and the bulk density is 0.8 ~ 1.35g/cm3. Low thermal conductivity. Good thermal shock resistance.

Usually, industrial alumina is used as raw material, and a small amount of soft clay and binder are mixed together to form mud. Foam or gas generation method is adopted to form, dry and burn at 1400~1550 C. It can be used for the thermal insulation layer of thermal equipment or the lining of thermal equipment directly acting with flame, but it is not suitable for the place directly eroded by molten slag. It also has high stability when used in reducing atmosphere The high service temperature can generally reach 1650 ℃, and the products with high purity can reach 1800 ℃.

Corundum brick refers to refractory products with alumina content greater than 90% and corundum as the main crystalline phase. High normal temperature compressive strength (up to 340mpa). High load softening start temperature (greater than 1700 ℃). Good chemical stability, strong resistance to acidic or alkaline slag, metal and liquid glass. The thermal shock stability is related to its microstructure. The corrosion resistance of dense products is good, but the thermal shock stability is poor.

Purpose:

It is mainly used in the firing zone and transition zone of cement kiln, lime kiln, zinc oxide rotary kiln, metal magnesium rotary kiln, ceramsite sand and other rotary kilns.

Performance benefits:

1. Improve the strength, wear resistance and corrosion resistance of the original products and prolong their service life.

2. Improve the thermal shock stability of products and overcome the cracking and peeling of lining bricks.

3. Adjust the change rate of the product line to make it closely combined with the equipment to avoid loose lining bricks or even falling bricks.

Latest News

Contact Us

Contact:

Phone:

Tel: +86-13488802085

Add: No. 16 Xinzhong North Street, Shunyi District, Beijing, China